Methods of Cutting Sheet Metal

Methods of Cutting Sheet Metal

There are many different ways of cutting sheet metal. You can get the job done by hand with tin snips, a shear, either kick shear or power shear or large cnc machinery like laser cutting for more precise cutting.

Below are some of the most common methods to fabricate and cut sheet metal:

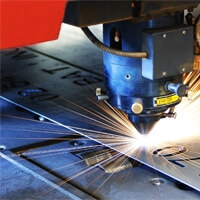

Laser Cutting

One of the latest methods of cutting sheet metal is laser cutting. In this operation, a specialized computer numerical control (CNC) laser is used to heat and burn the sheet metal, allowing a beam of laser light to pass through its surface. By permitting oxygen through the same nozzle from which the beam goes out, the sheet metal can be cut in a fast, smooth and precise manner.

Punching

Punching is another way of cutting sheet metal. This is carried out by moving the sheet of metal between the top and bottom tools of a punch machine. As compared to laser cutting, punching is less flexible in terms of cutting complicated shapes, but relatively faster in repetitive outlines. The grille of an air conditioning unit, for example, is usually made through punching.

Cutting Sheet Metal with Tin Snips

Sheet metal can also be fabricated and bent without using any machines. In fact, conventional hand tools such as a knife or axe along with a hammer will do the job. For hobbyists, cutting sheet metal with tin snips is a popular method, but a very tricky one. Sheet metal edges are sharp and the cutoffs are stiff, making it difficult to negotiate the curve. These dilemmas are common for those who don’t work with sheet metal on a regular basis. To successfully cut sheet metal using this traditional method, one must use the proper tools and know the necessary techniques.

You can choose from a wide array of tin snips in the market today, and selecting the right one can be a challenge. If you’re just a beginner, most experts recommend an offset compound tin snips. The cutters must be offset under the handle so you can maintain your cutting hand above the work. Because of the compound action, you’ll exert less time and effort even in cutting thicker material. Take note, however, that compound snips are color-coded and are not created similarly. A green snips, for instance, is created to cut clockwise curves. A red snips is for cutting counter-clockwise curves.

Cutting Sheet Metal with Aviation Snips

Aviation snips can also be used in cutting sheet metal. Such tools are very popular among sheet metal workers and people who work in construction projects. Using aviation snips is difficult and, to a certain extent, painful, because the worker is obliged to place his wrist in an awkward position in order to grasp the section to be cut. Aviation snips with the cutting edges offset from the handle, also known as upright snips, may help minimize this awkward posture.