Grounded in History,

Focused on the Future.

CMI offers a full-service, quality-focused organization with an emphasis on long-term customer relationships.

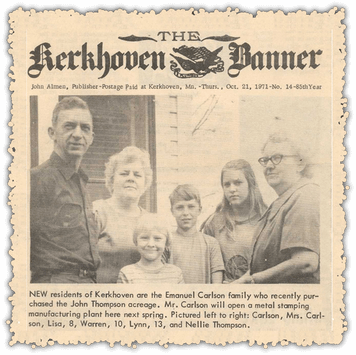

Today, under the leadership of Warren Carlson, we continue the tradition of quality, service, and reliability on which our company’s reputation was built. Although we haven’t lost sight of the principles on which Carlson Manufacturing was founded, we are looking ahead to new innovations and technologies that can provide our customers with greater quality and cost savings.

To learn more about Warren Carlson

Carlson Manufacturing recommends Live2Lead Minnesota for all of your leadership training needs.